SAMOA QUALITY AND LEADERSHIP

SAMOA INDUSTRIAL S.A., a privately owned company, is a leading European manufacturer of equipment for fluid transfer, dispensing, dosing, recovery and inventory control. SAMOA designs and manufactures volume flow meters, hose reels, air operated piston pumps and air operated diaphragm pumps, including innovative Directflo® diaphragm pumps. Product research and development is a fundamental part of SAMOA’s philosophy. SAMOA is in permanent contact with the market to identify new customer needs, that we satisfy with product improvements and new products. SAMOA’s headquarters have been in Gijón, on the Spanish North Coast, for over 60 years. SAMOA’s manufacturing facilities are modern and equipped with the latest state-of-the-art production equipment and technology. SAMOA is committed to design and manufacturing excellence, environmental sustainability and a healthy and safe workplace; our work processes and facilities are consequently ISO 9001, ISO 14001 and OHSAS 18001 certified.

AODD pumps with central flow technolgoy | Directflo®

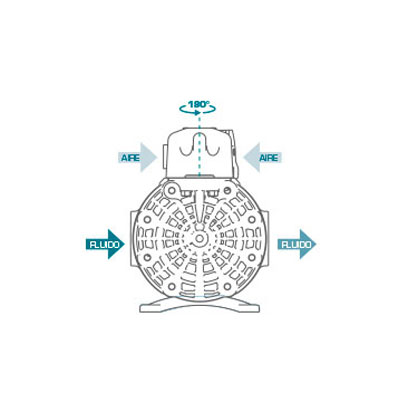

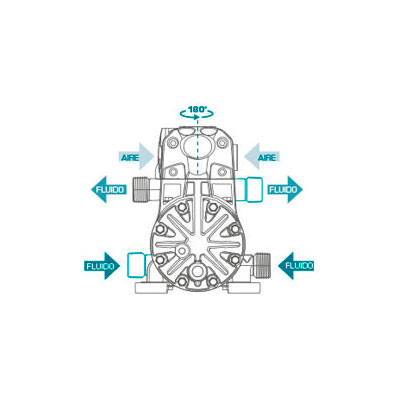

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids. For OEM applications and industrial processes with lower flow rates. Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure. Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene. Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

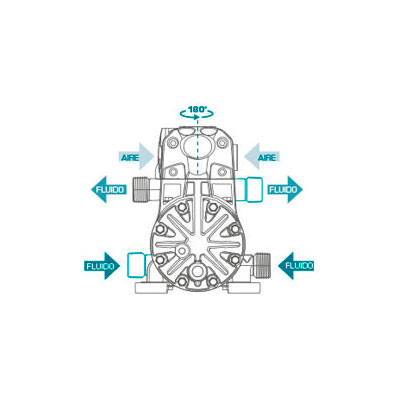

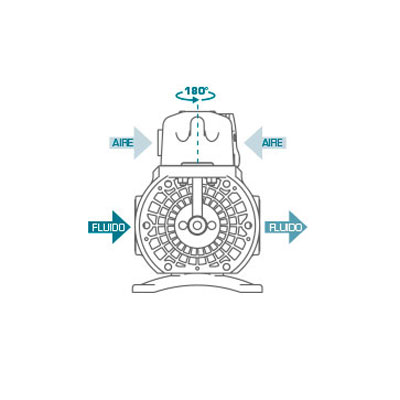

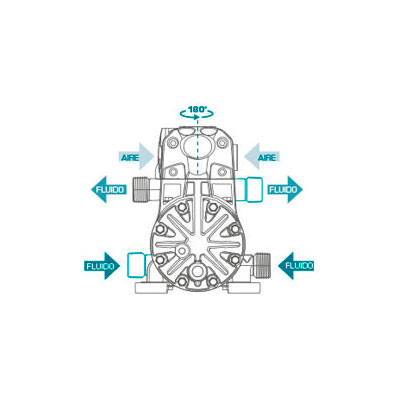

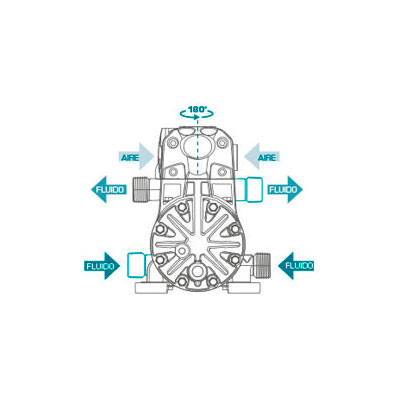

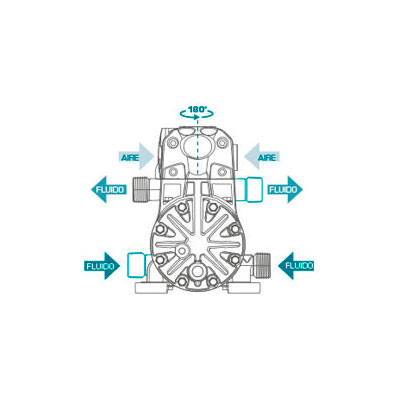

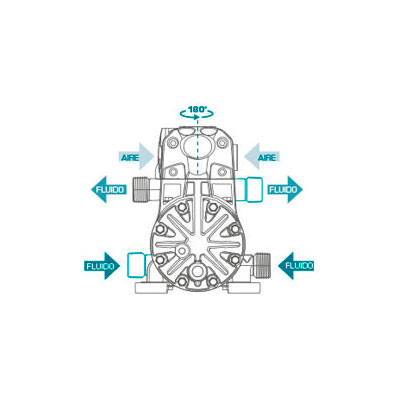

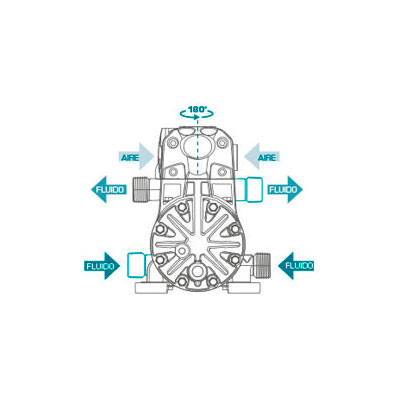

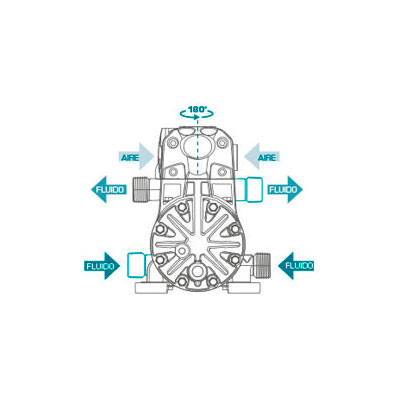

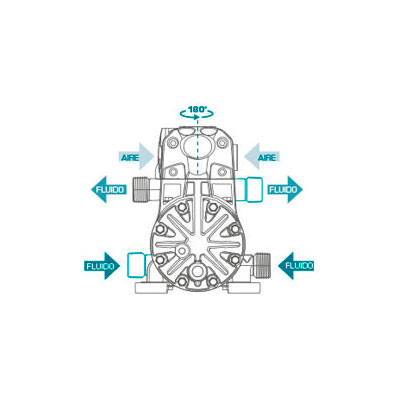

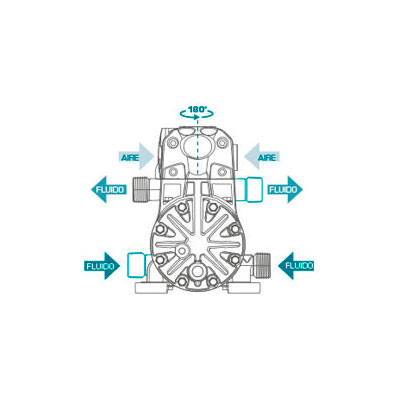

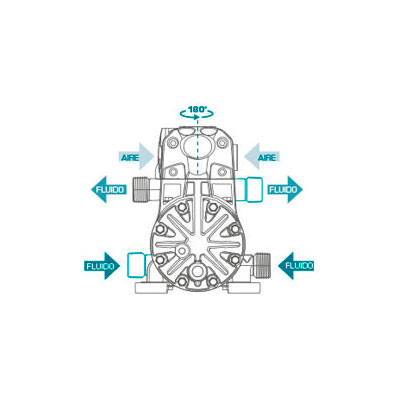

Directflo® pumps are based in an " inside-out" technology: the fluid is pumped through the centre of the pump and the compressed air acts on outside face of the diaphragms.

Plastic Directflo®

Plastic Directflo® diaphragm pump wetted bodies are compatible with even the most aggressive chemicals, and the plastic directional air valve and air chamber covers are suitable for use in corrosive environments.

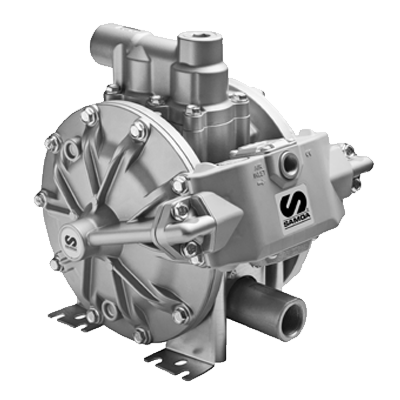

Metal Directflo®

Metal Directflo® diaphragm pumps are extremely robust and thanks to a wide range of wetted materials are compatible with many fluids.

| Pressure ratio | Maximum free delivery | Delivery per stroke approx. | Delivery per cycle (2 x strokes) | Air pressure operating range | Solids in suspension max. size | Maximum dry suction lift | Maximum wet suction lift | Weight | Fluid inlet connection | Fluid outlet connection | Air inlet connection | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DF50 | ||||||||||||

|

1:1 | 50 l/min (14 US gal/min) |

0.1 litres (0.026 US gal) |

0.2 litres (0.05 US gal) |

1.5 - 8 bar (22 - 115 psi) |

3 mm (1/8") |

6 m (20’) |

8 m (26’) |

3.5 kg (7.72 lb) |

Int.:1/2" BSP/NPT (F) | Int.:1/2" BSP/NPT (F) | 3/8" NPSM (F) |

| DF100 | ||||||||||||

|

1:1 | 100 l/min (28 US gal/min) |

0.25 litres (0.07 US gal) |

0.50 litres (0.13 US gal) |

1.5 - 8 bar (22 - 115 psi) |

4 mm (3/16") |

4.5 m (15’) |

7 m (23’) |

7.2 kg (16 lb) |

1" BSP/NPT (F) | 1" BSP/NPT (F) | 3/8" NPSM (F) |

| DF250 | ||||||||||||

|

1:1 | 250 l/min (66 US gal/min) |

0.6 litres (0.16 US gal) |

1.2 litres (0.32 US gal) |

1.5 - 8 bar (22 - 115 psi) |

6 mm (1/4") |

5 m (16’) |

8 m (26’) |

20 kg (45 lb) |

1 1/2" BSP (F) and DIN PN-10 DN40 flange or 1 1/2" NPT (F) and ANSI 1" B16.5 150 lb flange |

1 1/2" BSP (F) and DIN PN-10 DN40 flange or 1 1/2" NPT (F) and ANSI 1" B16.5 150 lb flange |

1/2" NPSM (F) |

| DP200 | ||||||||||||

|

1:1 | 200 l/min (53 US gal/min) |

0.5 litres (0.13 US gal) |

1 litres (0.26 US gal) |

1.5 - 8 bar (22 - 115 psi) |

6 mm (1/4") |

5 m (16’) |

8 m (26’) |

11.5 kg (23.35 lb) |

1" BSP/NPT (F) | 1" BSP/NPT (F) | 3/8" NPSM (F) |

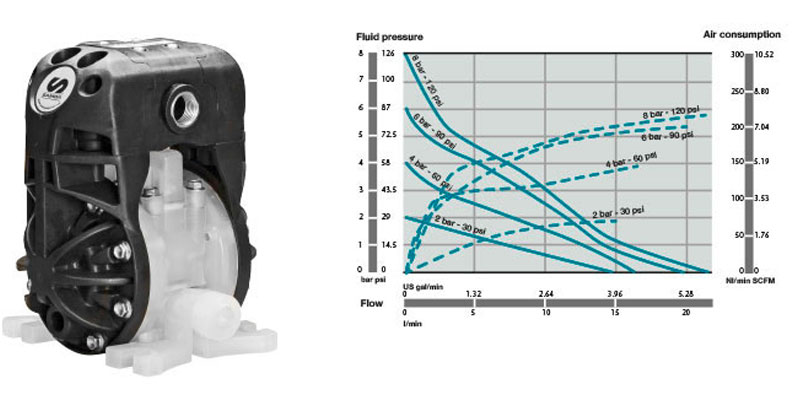

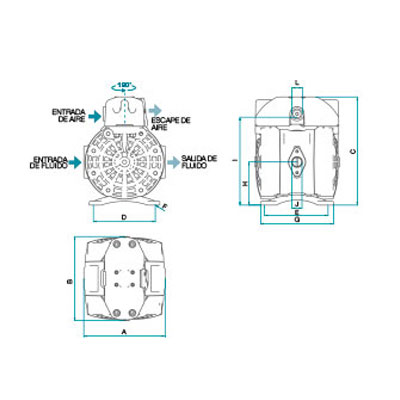

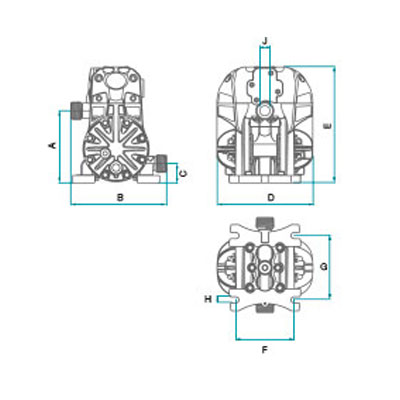

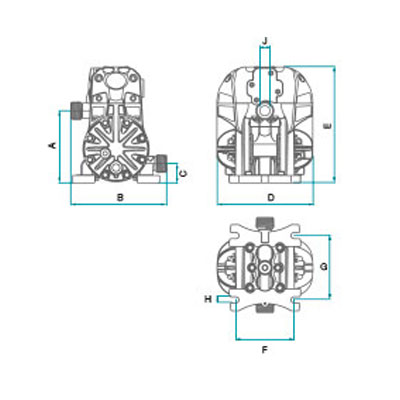

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

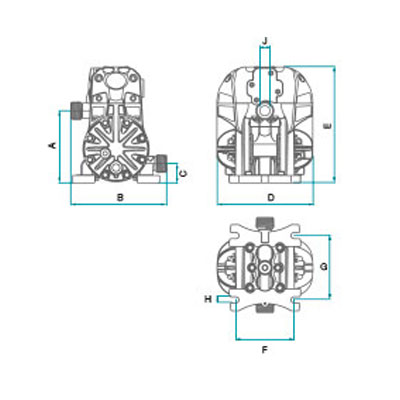

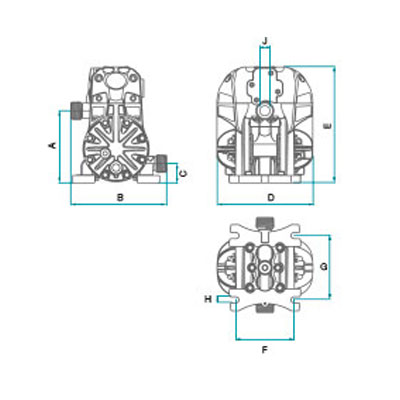

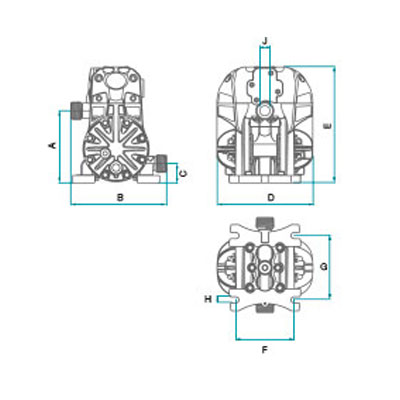

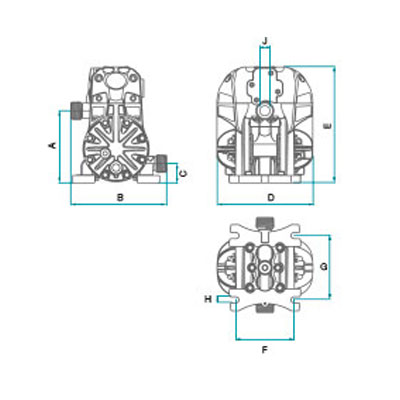

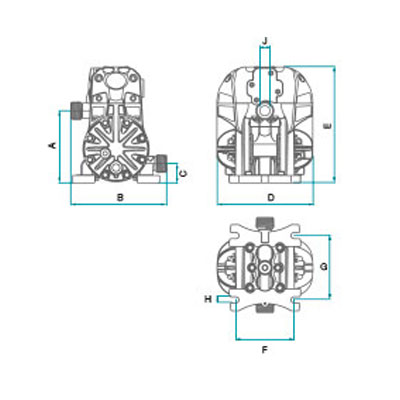

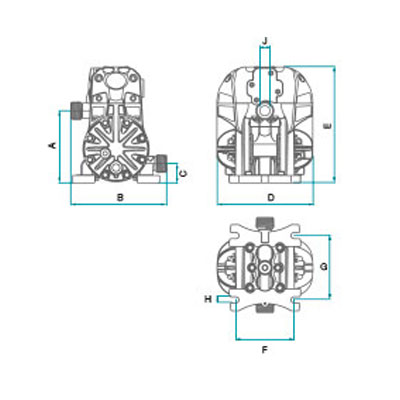

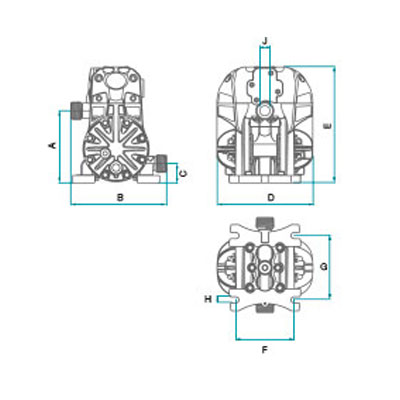

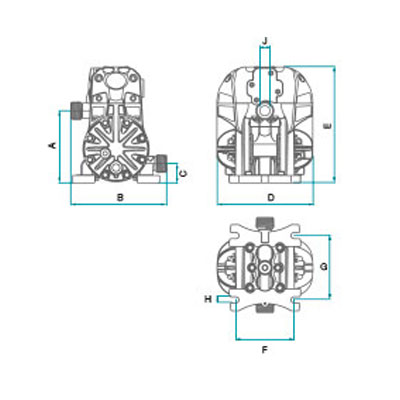

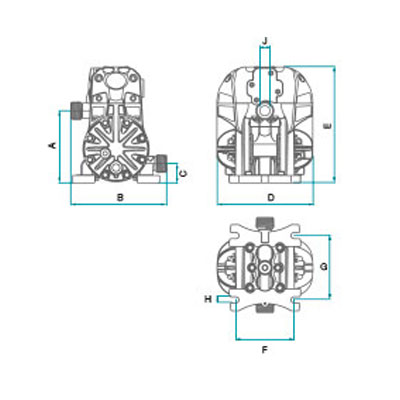

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

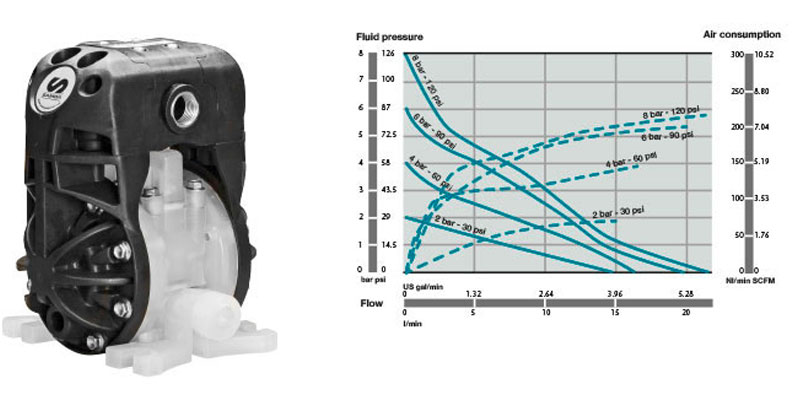

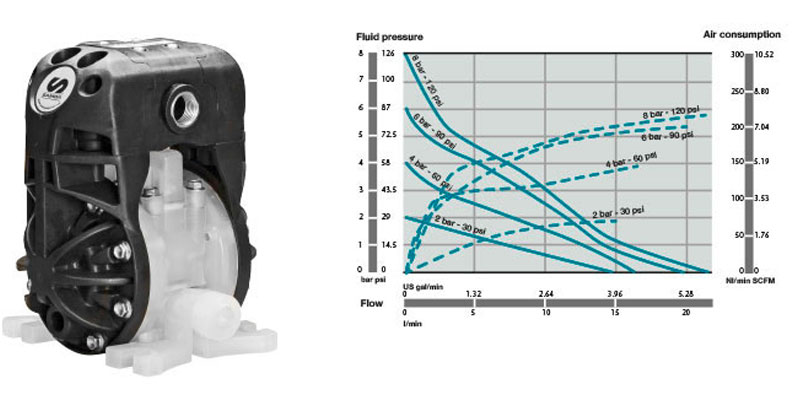

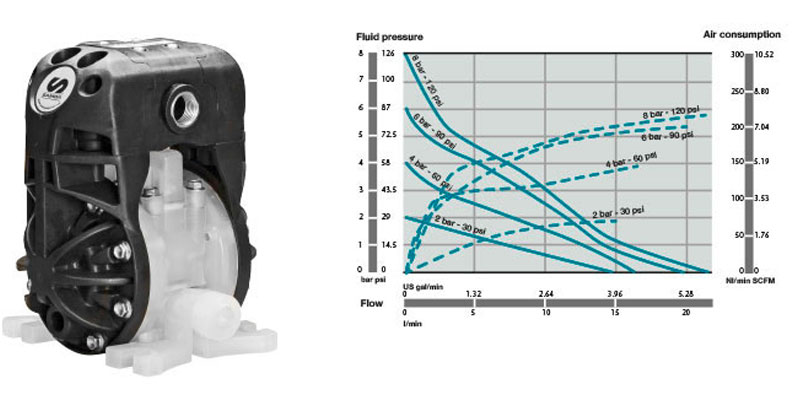

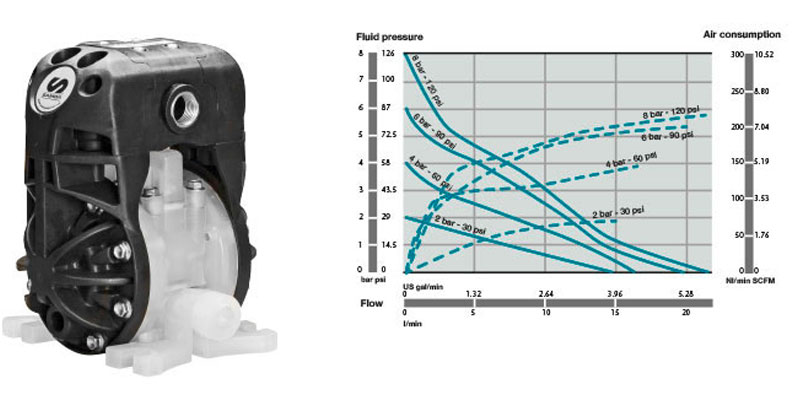

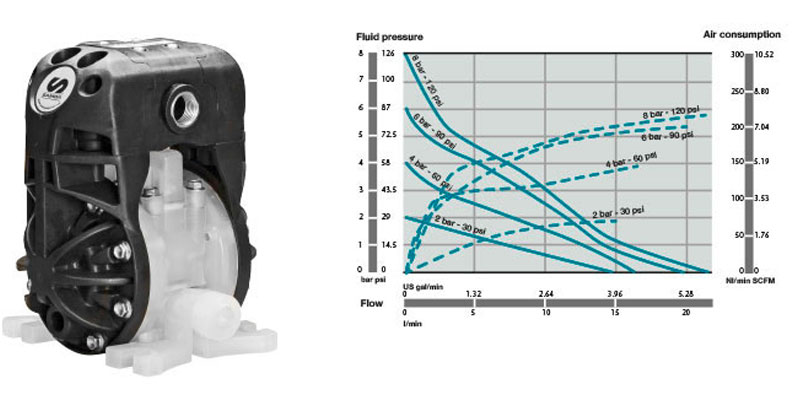

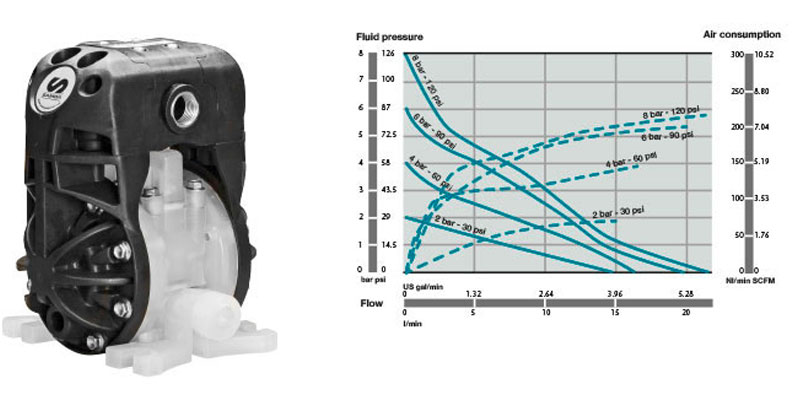

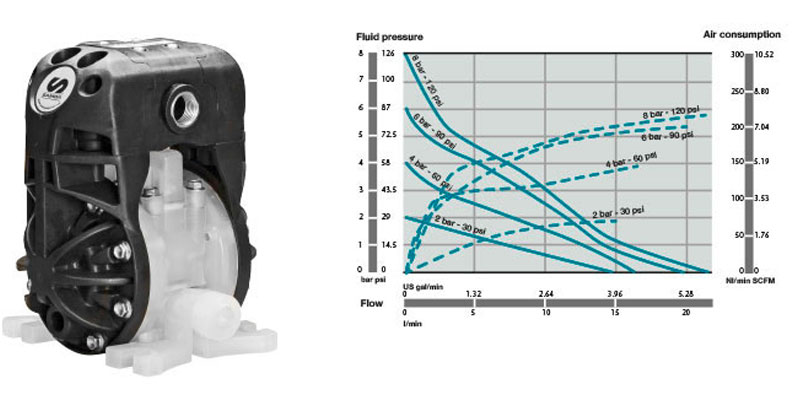

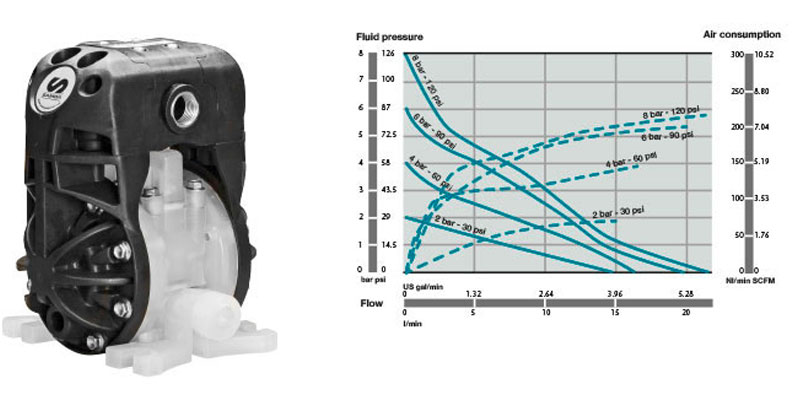

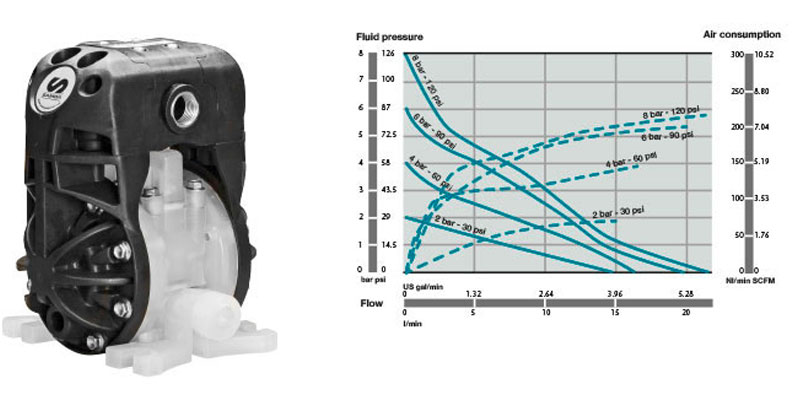

DC20 Plastic Pump Performance Curve

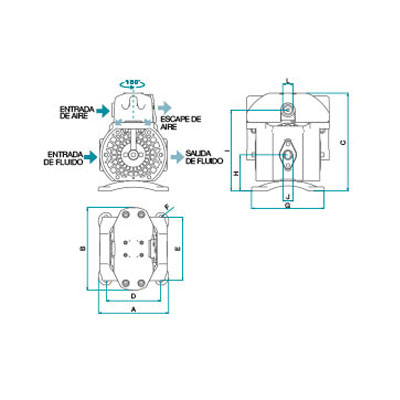

DC30 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 38 l/min (10 US gal/min) |

| Delivery per stroke approx. | 0.07 litres (0.02 US gal) |

| Delivery per cycle (2 x strokes) | 0.14 litres (0.04 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 3 mm (1/8") |

| Maximum dry suction lift | 4 m (13’) |

| Maximum wet suction lift | 8 m (26’) |

| Weight | 1.9 kg (4.19 lb) |

| Fluid inlet connection | 1/2" BSP/NPT (F) |

| Fluid outlet connection | 1/2" BSP/NPT (F) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F* |

| 135 | 160 | 189 | 105 | 122 | 8 |

| G | H | I | J | L | |

| 140 | 70 | 157 | 1/2" (F) | 3/8" (F) | |

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC30PPSESTMBAS | Polypropylene | Santoprene® | PTFE | StainlessSteel | EPDM | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC30PPSTSTTBAS | Polypropylene | PTFE | PTFE | Stainless Steel | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC30PPYTWTTBAS | Polypropylene | PTFE | PTFE | PVDF | Hastelloy® C | CIPs chlorinated cleaning agents and home & industrial cleaning agents. Acids and alkalis. |

| DC30PDSTSTTBAS | Conductive Acetal | PTFE | PTFE | Stainless Steel | Stainless Steel | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC30 Plastic Pump Performance Curve

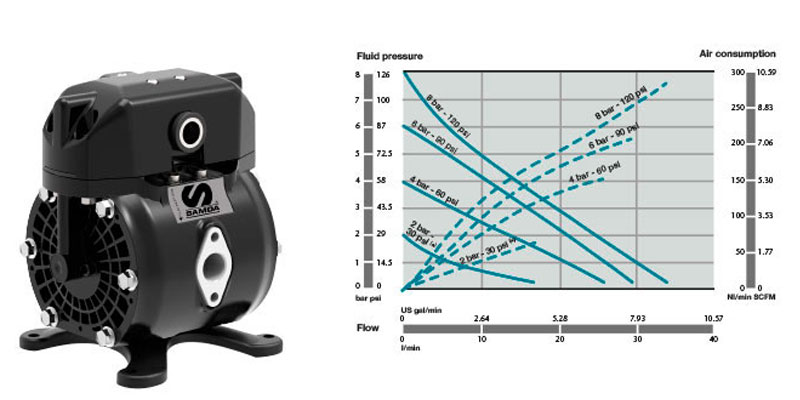

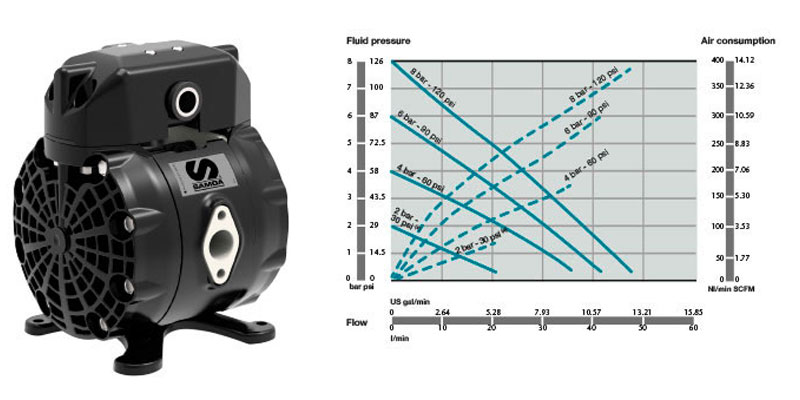

DC50 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 50 l/min (14 US gal/min) |

| Delivery per stroke approx. | 0.1 litres (0.026 US gal) |

| Delivery per cycle (2 x strokes) | 0.2 litres (0.05 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 3 mm (1/8") |

| Maximum dry suction lift | 6 m (20’) |

| Maximum wet suction lift | 8 m (26’) |

| Weight | 2.2 kg (4.85 lb) |

| Fluid inlet connection | 1/2" BSP/NPT (F) |

| Fluid outlet connection | 1/2" BSP/NPT (F) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F* |

| 156 | 162 | 209 | 105 | 122 | 8 |

| G | H | I | J | L | |

| 140 | 83 | 176 | 1/2" (F) | 3/8" (F) | |

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC50PPSESTMBAS | Polypropylene | Santoprene® | PTFE | Stainless Steel | EPDM | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC50PPSTSTTBAS | Polypropylene | PTFE | PTFE | Stainless Steel | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis |

| DC50PPYTWTTBAS | Polypropylene | PTFE | PTFE | PVDF | Hastelloy® C | CIPs chlorinated cleaning agents and home & industrial cleaning agents. Acids and alkalis. |

| DC50PDSTSTTBAS | Conductive Acetal | PTFE | PTFE | Stainless Steel | Stainless Steel | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC50 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

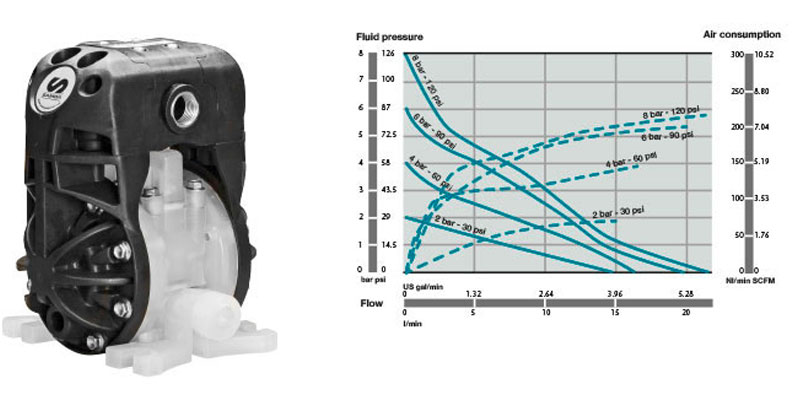

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 PLASTIC PUMPS

Air operated double diaphragm pumps for dosing and transferring a wide variety of fluids.

For OEM applications and industrial processes with lower flow rates.

Unbalanced spool valve air motor requires lower start-up pressure for fine flow adjustment using regulating air pressure.

Pump wetted materials are compatible with the most aggressive fluids and are suitable for use in corrosive environments. Air motor (directional air valve and air chamber covers) is made of polypropylene.

Fully groundable ATEX certified pumps are available for use in potentially explosive atmospheres (Ex II2 GD IIB/IIC 95 ˚C).

| TECHNICAL DATA | |

|---|---|

| Pressure ratio | 1:1 |

| Maximum free delivery | 20 l/min (5 US gal/min) |

| Delivery per stroke approx. | 0.03 litres (0.008 US gal) |

| Delivery per cycle (2 x strokes) | 0.06 litres (0.016 US gal) |

| Air pressure operating range | 1.5 to 7 bar (22 to 100 psi) |

| Solids in suspension max. size | 2 mm (3/32") |

| Maximum dry suction lift | 2 m (6 1/2’) |

| Maximum wet suction lift | 7 m (23’) |

| Weight | 1,2 kg (2.65 lb) |

| Fluid inlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Fluid outlet connection | Int.: 1/4" BSP/NPT (F) / Ext.: 3/4" NPT (M) |

| Air inlet connection | 3/8" NPSM (F) |

| Wetted part materials | See recommended models |

| DIMENSIONS (mm) | |||||

|---|---|---|---|---|---|

| A | B | C | D | E | F |

| 108 | 142 | 29 | 142 | 173 | 86 |

| G | H* | J | |||

| 96 | 9 | 1/4"-3/4" (F) |

|||

| Model | Pump body | Diaphragms | Balls | Seats | Other wetted materials | Recommended Applications |

|---|---|---|---|---|---|---|

| DC20PPSEPTMBAS | Polypropylene | Santoprene® | PTFE | Polypropylene | Stainless Steel, EPDM. | Water based fluids and adhesives, diluted alkalis and acids, alcohols and water based coatings. |

| DC20PPSVPTHBAS | Polypropylene | TPE | PTFE | Polypropylene | Stainless Steel,FKM. | Non aggressive aqueous chemical solutions, water. |

| DC20PPSTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Stainless Steel | Wide chemical compatibility. Good with acids and alkalis. |

| DC20PPYTPTTBAS | Polypropylene | PTFE | PTFE | Polypropylene | Hastelloy® C. | CIPs chlorinated cleaning agents and home industrial cleaning agents. Acids and alkalis. |

| DC20PWYTWTTBAS | PVDF | PTFE | PTFE | PVDF | Hastelloy® C. | Almost universal chemical pump, including strong acids and alkalis above room temperature. Not recommended for some strong alkalis or concentrated nitric acid. |

| DC20PPSEPTMBAS | Conductive Acetal | PTFE | PTFE | Acetal | Stainless Steel. | ATEX pump. Solvents (most ketones, acetates, aldehydes, aromatic and chlorinated hydrocarbons), solvent and water based flexo and gravure inks, varnishes and paint. |

(*) ATEX certifiedversions available, Ex II2 GD IIB/IIC 95 ˚C

(**) (Designs, pictures, dimensions and texts are not binding)

DC20 Plastic Pump Performance Curve

DC20 Plastic Pump Performance Curve